Introducing the most effective Quality Mining Equipment Parts for Enhanced Performance and Toughness

Wiki Article

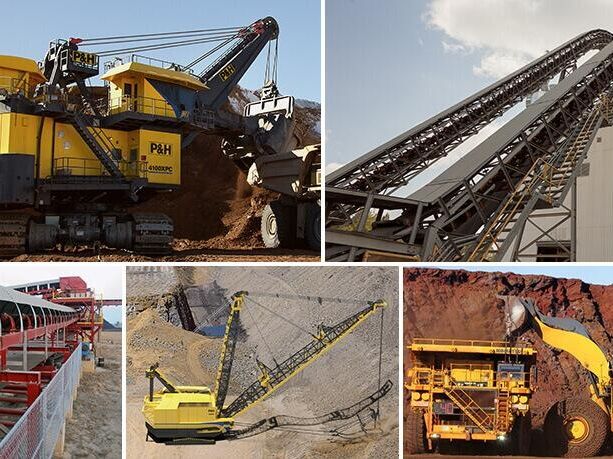

Unveiling Vital Mining Devices Parts for Optimum Operations

In the elaborate world of mining operations, the smooth functioning of tools is vital. Behind the scenes of every effective procedure lies a careful option of vital parts that play an important function in guaranteeing optimal efficiency. From drill bits that carve with rock with accuracy to conveyor systems that simplify material transport, each element is a gear in the machinery of efficiency. As we look into the midsts of mining devices fundamentals, a more detailed consider the elaborate details and functionalities of these components unveils an interesting world where efficiency and integrity are the foundations of success.Relevance of Correct Drill Little Bits

Appropriate selection and maintenance of drill little bits are fundamental for maximizing mining efficiency and productivity (mining equipment parts). The kind of drill bit selected have to line up with the certain geological conditions of the mining website to make sure optimum performance.Regular maintenance of drill bits is equally essential to guarantee durability and performance. Damaged or plain drill little bits can result in lowered boring rate, increased endure exploration devices, and ultimately, decreased productivity. Upkeep jobs might include sharpening, regrinding, or replacing used parts to maintain the drill bits in top working condition.

Key Elements in Conveyor Solutions

Reliable material transportation in mining operations heavily depends on the functionality and honesty of crucial components in conveyor systems. One crucial element is the conveyor belt itself, which lugs the materials along the mining website. The quality and sturdiness of the conveyor belt are vital to avoid breakdowns and ensure a smooth circulation of materials. Another important element is the idler, which supports the conveyor belt and aids preserve correct stress for reliable procedure. Idlers are strategically put along the conveyor system to decrease rubbing and support the weight of the products being carried - mining equipment parts.

Crucial Filters for Tools Maintenance

A crucial facet of guaranteeing the long life and optimum performance of mining tools hinges on the meticulous option and maintenance of crucial filters. Filters play an essential function in safeguarding mining equipment from contaminants that can cause deterioration, resulting in expensive repair services and downtime. Dirt, particles, and dirt are prevalent in mining settings, making the correct filtration system vital to tools longevity.Filters in mining equipment serve to catch fragments that might penetrate read the article sensitive elements such as transmissions, engines, and hydraulics. Regularly changing these filters according to supplier recommendations is essential to avoid clogging and guarantee effective operation. Overlooking filter maintenance can cause reduced devices life expectancy, decreased efficiency, and increased fuel consumption.

Important Use Parts for Crushers

In the world of mining tools upkeep, one crucial facet that requires focus is the recognition and replacement of essential wear parts for crushers. Crushers play a basic function in the ore handling and worldly reduction processes within mining procedures. Several of the key wear components that are crucial for the efficient performance of crushers consist of the adhering to:** Crusher Liners **: These are essential in securing the crusher shell from damage triggered by the material being squashed.

** Jaw Plates **: Found in jaw crushers, these components are accountable for squashing the material against a dealt with surface.

** Mantles and Concaves **: These parts are essential in gyratory crushers, where they assist in squashing the product right into a much more refined type.

Normal assessment and replacement of these wear parts are essential to make certain the crushers operate at their optimal effectiveness, decreasing downtime and taking full advantage of performance in why not check here mining procedures. Correct upkeep of these wear parts can considerably influence the general performance find more info and durability of the crushers, ultimately adding to the success of mining activities.

Duty of Hydraulic Cyndrical Tubes in Mining

Playing a crucial function in modern mining procedures, hydraulic cyndrical tubes are important elements that assist in the reliable functioning of different heavy machinery. These hydraulic cyndrical tubes are essential for powering essential mining equipment such as excavators, excavators, drills, and loaders.Hydraulic cyndrical tubes in mining devices are created to hold up against harsh operating conditions, consisting of severe temperature levels, high pressures, and heavy tons. In essence, hydraulic cyndrical tubes play a vital function in enhancing the efficiency and efficiency of mining operations worldwide.

Conclusion

Finally, it is essential for mining procedures to utilize appropriate drill bits, vital components in conveyor systems, critical filters for equipment upkeep, vital wear parts for crushers, and hydraulic cylinders. These important mining tools components play a substantial function in maximizing and making certain optimum procedures performance in the mining industry. By investing in top notch and trusted devices components, mining business can boost performance and minimize downtime, eventually leading to a much more successful operation.In the intricate world of mining operations, the smooth functioning of tools is vital. By investing in premium filtering systems and adhering to a stringent upkeep timetable, mining operations can boost devices dependability, lessen downtime, and ultimately maximize performance.

In the realm of mining tools upkeep, one important element that demands interest is the identification and substitute of essential wear parts for crushers. These crucial mining tools parts play a significant duty in optimizing and guaranteeing ideal procedures effectiveness in the mining market. By investing in reputable and high-grade tools parts, mining firms can enhance productivity and lessen downtime, ultimately leading to a more successful procedure.

Report this wiki page